General Capabilities

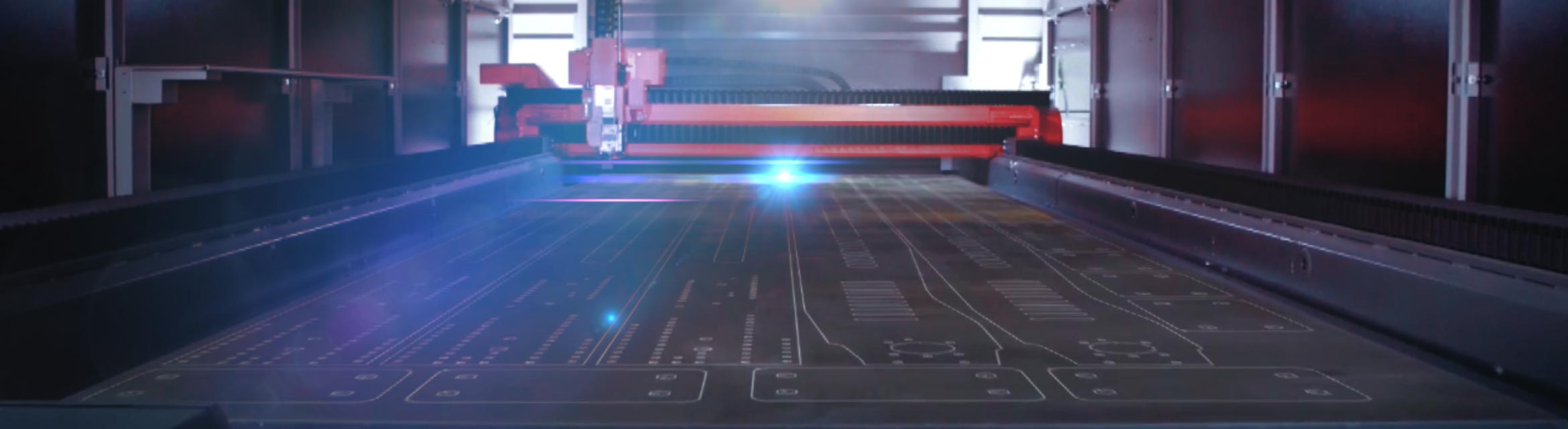

Fiber lasers are the newest development in laser cutting. The laser beam is created by an active fiber and transmitted over a transport fiber to the machine cutting head. Fiber lasers are significantly smaller than CO2 lasers and generate twice as much power from the same amount of current.

All of our lasers are connected to our Global Shop ERP system for lights out operation. PO to cutting takes less than 10 minutes regardless of how many lines are on the order. Hundreds of parts can be entered into the system and be available to cut at any time. This system allows late Friday orders and early Monday deliveries.

From simple angles to complex multi-bend parts our expertise and tooling can make the difference.

Insertion

Number of additional support pieces and backup stations

With a highly trained and experienced staff, we can analyze your designs and offer recommendations for reducing cost and increasing manufacturability. From concept to finished part, our engineering team will be with you at every step.

P: 866-986-0019 US Toll Free

P: 765-571-5125 ext 2250 Customer Service

HyFlex Corporation's passion for contract manufacturing started way back in 1964. Learn more.